I-ALLOY ENGATHUMELEKI IPIPIPI IPHAYIBHANA LESITHUBHU ESIPHEZULU SOkucindezela kwensimbi

Incazelo

I-OD: 6-720MM

I-WT: 0.5-120MM

Ubude: 3-16M

Isicelo: Petroleum, Chemical Engineering, Electricity, Boiler

Okujwayelekile:ASTM A335/A335M, ASTM A213/213M, DIN17175-79, JIS3467-88,GB5310-95

Impahla:P5,T5,P11,P12,STFA22,P22,T91,T9,WB36

Ipayipi le-alloy luhlobo lwepayipi lensimbi elingenamthungo, ukusebenza kwalo kuphakeme kakhulu kunepayipi lensimbi elingenamthungo, ngoba lolu hlobo lwepayipi lensimbi liqukethe i-Cr eyengeziwe, ukumelana kwayo nokushisa okuphezulu, ukumelana nokushisa okuphansi, ukusebenza kokumelana nokugqwala kungcono kakhulu kunezinye. Ipayipi lensimbi , ngakho-ke ipayipi ye-alloy isetshenziswa kabanziku-petroleum, i-aerospace, amakhemikhali, amandla kagesi, ubhayela, ezempi nezinye izimboni.

I-alloy tube ibhekisela ekusetshenzisweni kokucutshungulwa kwe-alloy extrusion ibe into yensimbi ye-tubular, engaba neyodwa noma ngaphezulu evaliwe ngezimbobo, ukushuba kodonga kanye nengxenye yesiphambano esifanayo, esetshenziswa ezimotweni, emikhunjini, e-aerospace, yezindiza, kagesi, ezolimo, i-electro mechanical, ikhaya nezinye izimboni.

Ukucaciswa

Ukwakheka Kwamakhemikhali

| C, % | Mn, % | P, % | S, % | Si, % | Cr, % | Mo, % |

| 0.05-0.15 | 0.30-0.60 | 0.025 ubuningi | 0.025 ubuningi | 0.50-1.00 | 1.00-1.50 | 0.44-0.65 |

Izakhiwo Zemishini

| Amandla Okuqina, MPa | Isivuno Amandla, MPa | Ubude, % |

| 415 imiz | 205 imiz | 30 imiz |

Ngaphandle Ububanzi & Ukubekezelelana

|

I-ASTM A450

| Okushisayo kugoqiwe | Ngaphandle Ububanzi, mm | Ukubekezela, mm |

| OD≤101.6 | +0.4/-0.8 | ||

| 101.6<OD≤190.5 | +0.4/-1.2 | ||

| 190.5<OD≤228.6 | +0.4/-1.6 | ||

| I-ASTM A530 ne-ASTM A335 | I-NPS | Ngaphandle Ububanzi, iyintshi | Ukubekezela, mm |

| 1/8≤OD≤1-1/2 | ±0.40 | ||

| 1-1/2<OD≤4 | ±0.79 | ||

| 4<OD≤8 | +1.59/-0.79 | ||

| 8<OD≤12 | +2.38/-0.79 | ||

| OD>12 | ±1% |

Ukuqina kwezindonga & Ukubekezelelana

| I-ASTM A450 | Okushisayo kugoqiwe | Ngaphandle Ububanzi, mm | Ukubekezela, % |

| OD≤101.6, WT≤2.4 | +40/-0 | ||

| OD≤101.6, 2.4<WT≤3.8 | +35/-0 | ||

| OD≤101.6, 3.8<WT≤4.6 | +33/-0 | ||

| OD≤101.6, WT>4.6 | +28/-0 | ||

| OD>101.6, 2.4<WT≤3.8 | +35/-0 | ||

| OD>101.6, 3.8<WT≤4.6 | +33/-0 | ||

| OD>101.6, WT>4.6 | +28/-0 | ||

| I-ASTM A530 | I-NPS | Ngaphandle Ububanzi, iyintshi | Ukubekezela, % |

| 1/8≤OD≤2-1/2 | +20.0/-12.5 | ||

| 3≤OD≤18, WT/OD≤5% | +22.5/-12.5 | ||

| 3≤OD≤18, WT/OD>5% | +15.0/-12.5 | ||

| OD≥20, WT/OD≤5% | +22.5/-12.5 | ||

| OD≥20, WT/OD>5% | +15.0/-12.5 |

Okujwayelekile

I-ASTM A335–yepayipi lensimbi elingenamthungo leFerritic Alloy-Steel for High-Temperature Service

I-ASTM A519-ye-Seamless Carbon kanye ne-Alloy Steel Mechanical Tubing

I-ASTM A213–ye-Seamless Ferritic kanye ne-Austenitic Alloy-Steel Boiler, i-heater eyiSuper, kanye namashubhu okushintshanisa ukushisa

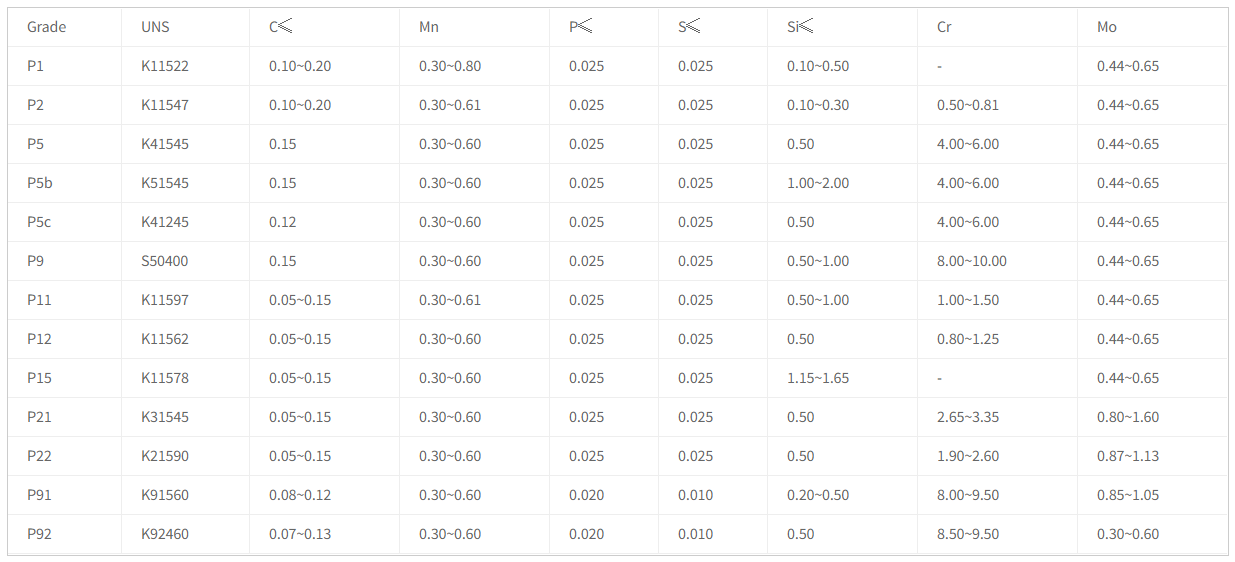

I-ASTM ASME (S)A-335/(S)A-335M Ibanga Nokubunjwa Kwekhemikhali

Qaphela: (S)A335 P91 okunye ukwakheka kwamakhemikhali : V 0.18~0.25;N 0.030~0,070;Ni ≤ 0.40;Al ≤ 0.04 ;Nb 0.06~0.10

(S)A335 P92 okunye ukwakheka kwamakhemikhali : V 0.15~0.25;N 0.030~0,070;Ni ≤ 0.40;Al ≤ 0.04 ;Nb 0.04~0.09;W 1.5~2.00 ;B 0.001~0.006

I-Painting & Coating

Ukugqoka okumnyama, uwoyela/i-varnish, i-FBE, i-2PE, i-3PE, uthayela njll Imininingwane yokupakisha: Ukupakisha ngezinqwaba noma ngokwesidingo seklayenti

Ukupakisha&Kuyalayisha